COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

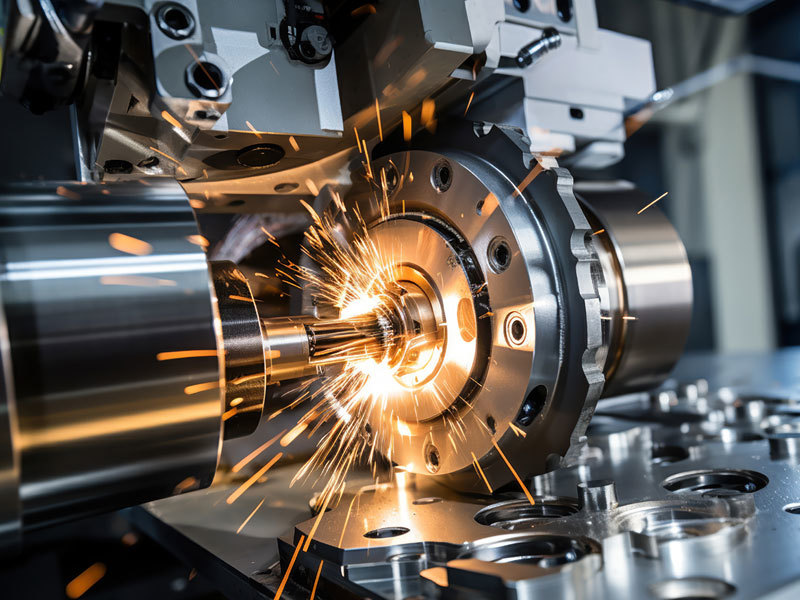

Metal forming and manufacturing

Size: according to the drawing/requirement

Description: Custom-made components for the metal forming mold industry. Carbide grades and designs are tailored to meet each customer's specific needs and requirements.

Zhuzhou Jinxin Carbide has 16 years of experience in the metal forming die industry. We can provide you with professional solutions.

Carbide drawing die

Carbide profile die blank

Stretch mold for the lithium battery

Stamped motor core die

In the metal extrusion process, the external force used to push the metal through the die compresses the metal's cross-sectional area, ultimately achieving the desired cross-sectional shape and size. Carbide drawing dies have a wide range of applications; their high hardness, excellent thermal conductivity, low coefficient of friction, and other properties make them a crucial component in the production of various metal wires, tubes, and profiled products.

Tungsten carbide blank profiles are widely used in the manufacturing of specially shaped drawing dies, with hole configurations within the die including round, triangular, pentagram, hexagonal, oval, and many other shapes. They are ideal for drawing coated electromagnetic profiled wires, stainless steel profiled wires, and various types of both ferrous and non-ferrous metals—such as components for electronic devices, tool keys, and more. Additionally, these custom-shaped dies can also be employed in multiple applications involving copper rods and other specialized wire-drawing industries, offering a flexible production solution tailored to meet the unique demands of drawing different profiled wire types.

The product series for the lithium battery casing stretch mold includes the round casing stretch bar and the concave mold, as well as the concave mold for stretching square casings. It is primarily used for high-speed stretching processes of both round steel casings for lithium batteries and square aluminum casings. The molds exhibit excellent wear resistance and impact strength, directly influencing the quality and efficiency of the lithium battery casing stretching process.

The motor core stamping die, along with the engine manufacturing process, is continuously evolving, and modern high-speed precision stamping technology is increasingly being applied to the production of motor cores. Since motor cores demand high dimensional accuracy and long tool life, it is especially crucial to use high-quality carbide materials for core stamping. Factors such as mold machining precision, punch press accuracy, and core material quality will all influence the lifespan of the mold material—and these are key considerations when selecting the appropriate mold material.

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha