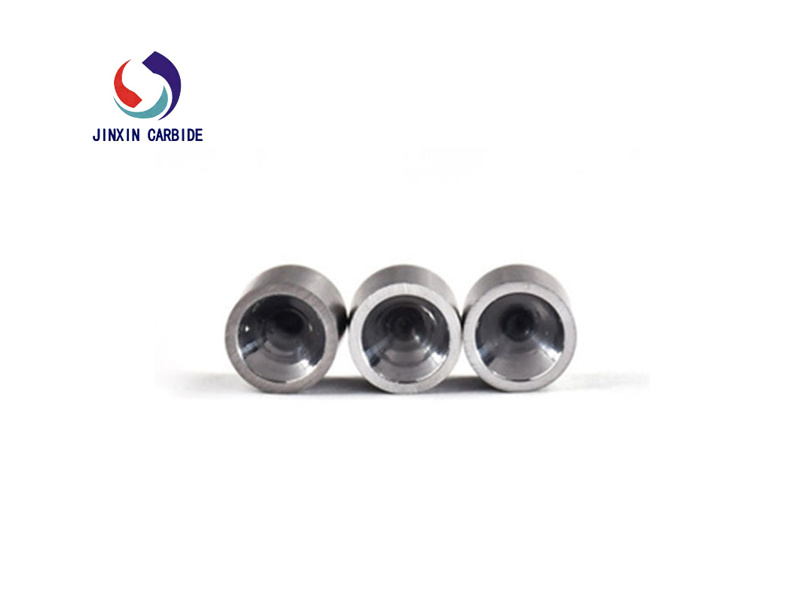

Carbide nozzle

Share with

Product Description

Product introduction

The cemented carbide nozzle is a device made from cemented carbide material, used to control the direction, speed, and flow rate of fluids. It is primarily composed of hard compounds of refractory metals (such as tungsten carbide) and binding metals (like cobalt), manufactured through a powder metallurgy process. After several processes—including powder preparation, mixing, pressing, presintering, shaping, sintering, and finishing—the nozzle is ensured to deliver high precision and excellent performance.

Product features

High hardness and wear resistance: the hardness can reach approximately HRA86–93, flexural strength reaches 2300 N/mm², and it can withstand impact as well as friction from high-velocity fluids. Additionally, its wear rate remains slow even in harsh environments such as sandblasting and shot peening.

Corrosion resistance: it can withstand corrosion from aggressive media such as acids, alkalis, and salts, making it suitable for working environments involving corrosive fluids, such as chemical and agricultural production.

High-temperature resistance: The hardness remains virtually unchanged at 500°C and still exhibits high durability at 1000°C, allowing for stable operation in high-temperature environments.

High precision: Through precision grinding and surface treatment processes, a surface roughness of Ra0.1 and Ra0.025 can be achieved on both R parts, ensuring high dimensional accuracy and guaranteeing the precision and stability of the spray application.

Areas of application

Surface treatment: widely used in sandblasting and shot blasting equipment for the descaling and polishing of metal machinery and cast parts, as well as for etching glass artworks.

Spray applications—such as painting, material spraying, and 3D printing—can evenly atomize liquid materials, enhancing the quality and efficiency of the spraying process.

Oilfield exploration: it is used for cleaning, cooling, lubricating, and removing bottomhole debris in PDC drill bits and roller cone drill bits.

Other areas: It can also be used in the chemical, food, mechanical, metallurgical, and construction industries for spraying, derusting, cleaning, atomization, and more, as well as for high-pressure cleaning, dust removal, cooling, desulfurization, humidification, and agitation.

Product parameters

Main degrees: YG6, YG8, YG10X, YG15, YN8, etc.

| Grade |

WC |

Co/Ni |

Physical and mechanical properties |

Size of grain |

Recommended application |

||

| Density |

TRS |

Hardness |

|||||

| YG6 |

94 |

6 |

14.8–15.1 |

2500 |

90 |

1.2 |

Good wear resistance, good compressive strength, Suitable for wear-resistant and high-pressure parts Durable parts, good thermal rigidity |

| YG6X |

94 |

6 |

14.8–15.1 |

2400 |

91.5 |

1 |

|

| YG6A |

94 |

6 |

14.8–15.1 |

2150 |

92.5 |

0.6–0.8 |

|

| YG8 |

92 |

8 |

14.6–14.9 |

2700 |

89 |

1.2–1.6 |

Good overall performance, used for everyday tasks Wear-resistant parts, molds, general-purpose tools, etc. |

| YL10.2 |

90 |

10 |

14.3–14.6 |

3800 |

91.8 |

0.7 |

Subfine tungsten carbide particles, Good overall performance |

| YG10X |

90 |

10 |

14.3–14.6 |

4000 |

92.2 |

0.6 |

Ultrafine tungsten carbide particles, Excellent heat resistance |

| YG11 |

89 |

11 |

14.3–14.7 |

2800 |

88.5 |

1.2–1.6 |

Anti-wear, anti-erosion, excellent overall mechanical strength Resistance, suitable for wear-resistant parts in the oil, chemical, and mechanical industries. |

| YG12X |

88 |

12 |

14.2–14.5 |

3000 |

89.5 |

1.0–1.2 |

Anti-erosion, excellent overall mechanical resistance, Suitable for wear- and impact-resistant parts parts, molds, and roller rings. |

| YG15 |

85 |

15 |

13.8–14.2 |

3000 |

86.5 |

1.2–1.6 |

|

| YG15X |

85 |

15 |

13.8–14.2 |

4500 |

89 |

0.7 |

Subfine tungsten carbide particles with excellent wear resistance resistance and excellent toughness, which is suitable for manufacture of integral stamping dies, anti-vibration tool holders, etc. |

| YG20 |

80 |

20 |

13.4–13.8 |

3100 |

85 |

1 |

Excellent wear resistance and toughness |

| YN06 |

94 |

6 |

14.5–14.9 |

2000 |

90 |

1.2 |

Non-magnetic alloy, suitable for O-rings, Non-magnetic, wear-resistant parts and corrosion-resistant parts. |

| YN09 |

91 |

9 |

14.3–14.6 |

2300 |

89 |

1.2–1.6 |

|

| YN11 |

89 |

11 |

14.0–14.3 |

2600 |

88 |

1.2 |

|

Size: Drilling, grooving, thread grinding, wire cutting, electrical discharge machining, thermal upsetting of steel parts, bevelling, polishing, and more can be performed.

Category:

Custom Wear Parts

Key word:

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products