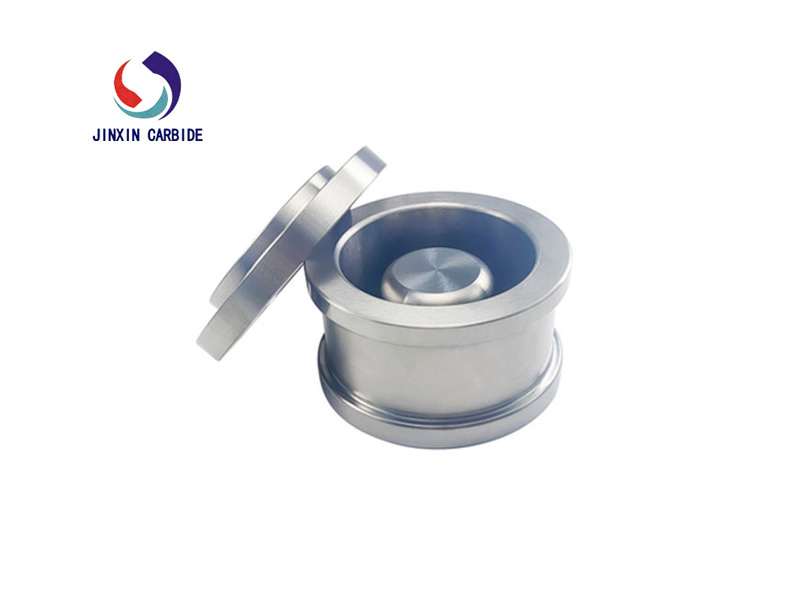

Cemented Carbide Ball Mill

Share with

Product Description

Product introduction

The cemented carbide ball mill, also known as the tungsten carbide ball mill, is made from hard compounds of refractory metals and binding metals through a powder metallurgy process. Its main components are tungsten carbide and cobalt.

The ball mill is the main component of the ball mill, whose primary function is to grind, mix, or disperse materials by combining them with grinding balls (such as steel balls, ceramic balls, cemented carbide balls, etc.), including:

Material refinement: Through the impact, compression, and friction generated by the high-speed rotation or vibration of grinding balls inside the mill, materials in block or granular form are broken down into fine powder—down to nanometer-level powder—meeting the required material fineness specifications.

Uniform mixing: When grinding several materials with different components, a uniform blend of the materials is achieved, ensuring consistent distribution of the material components even after mixing. This process is ideal for preparing alloys and developing composite materials.

Product features

High hardness: even at a temperature of 1000°C, it retains its high hardness, making it suitable for grinding ultra-hard powders such as cemented carbide, diamond, and emery.

High wear resistance: at a temperature of 500°C, its wear resistance remains virtually unchanged, effectively reducing wear caused by friction and impact, thus extending its service life.

High strength and good toughness: it exhibits high resistance and can withstand impact forces during the grinding process, while also maintaining excellent toughness, making it difficult to break or damage.

Resistance to high temperatures and corrosion: it can operate normally at temperatures up to 1000 ℃ and exhibits excellent resistance to corrosion from acids, alkalis, and other chemical substances.

High grinding efficiency: With a reasonably designed structure and uniform friction, combined with cemented carbide grinding balls, it generates significant energy between the grinding balls, materials, and the wall of the ball mill, which can markedly enhance grinding efficiency and improve the precision of material grinding.

Without contamination: the material is pure and will not contaminate the materials during the grinding process, ensuring the purity of the ground materials.

Areas of application

Powder metallurgy: it is used for grinding and preparing metallic powders, such as tungsten alloys, cemented carbides, and aluminum alloys.

Materials science: it is used for the preparation and research of nanomaterials, such as nanoiron, nanosilicon, and nanocarbon.

Chemical engineering: it is used for the synthesis and research of active substances and fine chemicals, such as cosmetics, dyes, and synthetic resins.

Electronic materials: used in the preparation and research of semiconductors, ceramics, and magnetic materials such as ferrites, aluminum oxide, and antimony oxide.

Pharmaceutical industry: it is used for grinding, preparation, and research of fine medicinal powders, such as micropulverization of traditional Chinese medicine and microparticles of Western pharmaceuticals.

Product parameters

Reference number: The commonly used reference number is YG8.

Grade | WC | Co/Ni | Physical and mechanical properties | Grain size | Recommended application | ||

Density | Tensile strength | Hardness | |||||

YG6 | 94 | 6 | 14.8–15.1 | 2500 | 90 | 1.2 | Good wear resistance, good compressive strength, Suitable for wear-resistant and high-pressure parts Resistance to parts, good thermal rigidity |

YG6X | 94 | 6 | 14.8–15.1 | 2400 | 91.5 | 1 | |

YG6A | 94 | 6 | 14.8–15.1 | 2150 | 92.5 | 0.6–0.8 | |

YG8 | 92 | 8 | 14.6–14.9 | 2700 | 89 | 1.2–1.6 | Good overall performance, used for everyday tasks Wear-resistant parts, molds, general-purpose tools, etc. |

YL10.2 | 90 | 10 | 14.3–14.6 | 3800 | 91.8 | 0.7 | Subfine tungsten carbide particles, Good overall performance |

YG10X | 90 | 10 | 14.3–14.6 | 4000 | 92.2 | 0.6 | Ultrafine tungsten carbide particles, Excellent heat resistance |

YG11 | 89 | 11 | 14.3–14.7 | 2800 | 88.5 | 1.2–1.6 | Wear-resistant, erosion-resistant, with excellent overall mechanical strength, Suitable for wear-resistant parts in the oil, chemical, and mechanical industries. |

YG12X | 88 | 12 | 14.2–14.5 | 3000 | 89.5 | 1.0–1.2 | Anti-erosion, excellent overall mechanical resistance, suitable for wear- and impact-resistant parts, molds and roller rings. |

YG15 | 85 | 15 | 13.8–14.2 | 3000 | 86.5 | 1.2–1.6 | |

YG15X | 85 | 15 | 13.8–14.2 | 4500 | 89 | 0.7 | Subfine tungsten carbide particles with excellent wear resistance and excellent tenacity, which is suitable for manufacture of integral stamping dies, anti-vibration tool holders, etc. |

YG20 | 80 | 20 | 13.4–13.8 | 3100 | 85 | 1 | Excellent wear resistance and toughness |

YN06 | 94 | 6 | 14.5–14.9 | 2000 | 90 | 1.2 | Non-magnetic alloy, suitable for O-rings, Non-magnetic, wear-resistant parts and corrosion-resistant parts. |

YN09 | 91 | 9 | 14.3–14.6 | 2300 | 89 | 1.2–1.6 | |

YN11 | 89 | 11 | 14.0–14.3 | 2600 | 88 | 1.2 | |

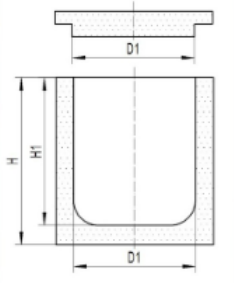

Dimensions

| Parameters Specifications (mm) | H1 | H | D1 |

0.05L | 46 | 52 | φ38 | |

0.1L | 50 | 59 | φ51 | |

0.25L | 61 | 69 | φ73 | |

0.5L | 88.5 | 96 | φ90 | |

1L | 98 | 110 | φ115 |

Generally, it is manufactured according to the customer's drawings.

Category:

Custom Wear Parts

Key word:

Cemented Carbide Ball Mill

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products