COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Cemented Carbide Button and Carbide Insert

Share with

Product Description

Product introduction

Cemented carbide ball teeth (tungsten carbide button) are also referred to as cemented carbide teeth (tungsten carbide insert), and they are primarily used in drilling, mining, engineering machinery, and other industries. They feature extremely high hardness and excellent resistance to impact. Their surface hardness can reach HRA92-94, allowing them to withstand high-intensity impact loads without fracturing. Additionally, cemented carbide ball teeth can be customized with varying compositions and structures tailored to specific application conditions, ensuring efficient drilling even in complex geological settings.

The cemented carbide ball teeth from Zhuzhou Jinxin are manufactured using high-purity tungsten powder with a tungsten content of ≥99.95%, achieving superior strength and hardness performance. This results in longer tool life for bottom-hole drill bits. The teeth are pressed using a precision isostatic press, ensuring uniform density throughout. The continuous teeth are then sintered in a pressure sintering furnace, enhancing the product's wear resistance by up to 24%. Finally, they are precisely ground on a centerless grinder, delivering dimensional accuracy down to 0.8 microns.

Product parameters

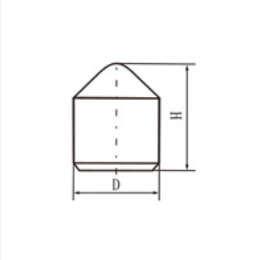

| Conical teeth | Product model | Basic dimensions (mm) | |

| Diameter | Height | ||

| 082130ZD1A | 8.2 | 13 |

| 100140ZD0A | 10 | 14 | |

| 122170ZD0A | 12.2 | 17 | |

| 142200ZD1A | 14.2 | 20 | |

| 164240ZD0A | 16.4 | 24 | |

| 190250ZD1A | 19 | 25 | |

| 220260ZSOA | 22 | 26 | |

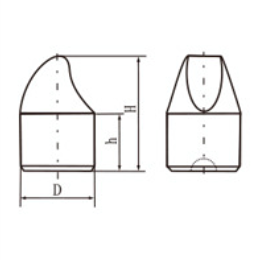

| Teeth shaped like spoons | Product model | Basic dimensions (mm) | |

| Diameter | Height | ||

| 133170SD0A | 13.3 | 17 |

| 142210SD1A | 14.2 | 21 | |

| 162240SD0A | 16.2 | 24 | |

| 185270SDOA | 18.5 | 27 | |

| 202290SD1A | 20.2 | 29 | |

| 220320SD0A | 22 | 32 | |

| 262330SD1A | 26.2 | 33 | |

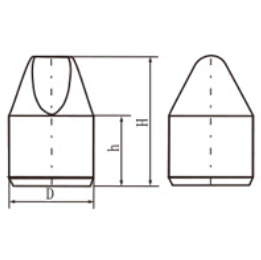

| Wedge-shaped teeth | Product model | Basic dimensions (mm) | |

| Diameter | Height | ||

| 100150XD1A | 10 | 15 |

| 122170XD0A | 12.2 | 17 | |

| 142210XD1A | 14.2 | 21 | |

| 162230XD0A | 16.2 | 23 | |

| 182260XD1A | 18.2 | 23 | |

| 203310XD0A | 20.3 | 31 | |

| 290450XD1A | 29 | 45 | |

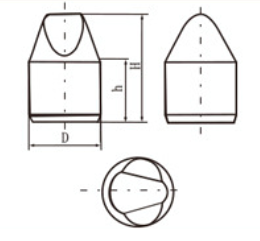

| Wedge-shaped lateral teeth | Product model | Basic dimensions (mm) | |

| Diameter | Height | ||

| 142200BD0A | 14.2 | 20 |

| 164220BD1A | 16.4 | 22 | |

| 188250BD0A | 18.8 | 25 | |

| 200260BD1A | 20 | 26 | |

| 224300BD0A | 22.4 | 30 | |

Category:

Cemented Carbide Button

Key word:

Tungsten Carbide Button

Carbide Insert

Carbide Tips

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha