COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

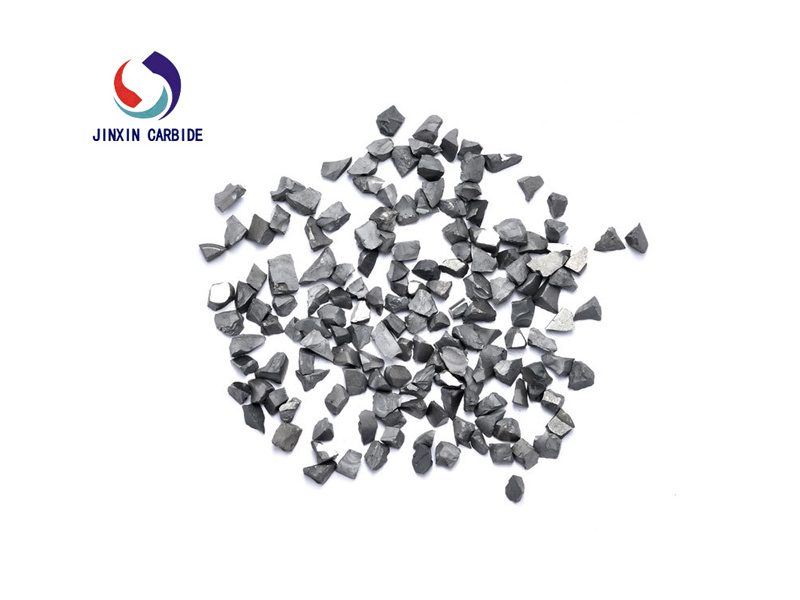

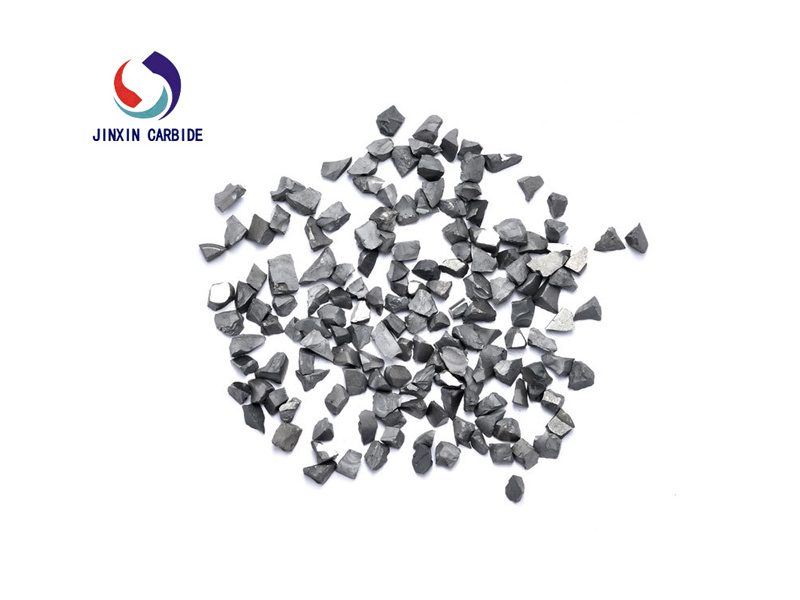

Cemented carbide particles

Share with

Product Description

Product introduction

Cemented carbide particles, also known as crushed cemented carbide particles, are made from sintered tungsten carbide material, with an optimized and carefully controlled cobalt content ranging from 5% to 12%. This ensures the particles’ wear resistance as well as their strong bonding to the metallic matrix. The nickel-copper alloy matrix contains between 30% and 35% copper, boasting a density of 14.8 g/cm³ and providing a robust support base with a tensile strength of 690 MPa. Additionally, a special flux coating can minimize oxidation reactions during the layer-welding process, ensuring a uniform and orderly distribution of the alloy particles.

The cemented carbide particle product is primarily used for repairing worn parts in industries such as oil drilling, mining machinery, and construction, making it particularly suitable for overlay welding of wear-resistant layers on tools like twist drills, milling shoes, and wear shoes. The overlay welding process employs an oxyacetylene flame, requiring the use of a neutral or slightly carburizing flame for preheating; after welding, slow cooling must be carried out to ensure weld quality.

Size of cemented carbide particles

Mesh 145-325 |

Mesh 20-30 |

Mesh 1.6-3.2 |

Mesh 3.2-4.8 |

Mesh 4.8–6.4 |

Mesh 6.4-8 |

Category:

Cemented Carbide Hardfacing

Key word:

Cemented Carbide Particles

Tungsten Carbide Grits

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha