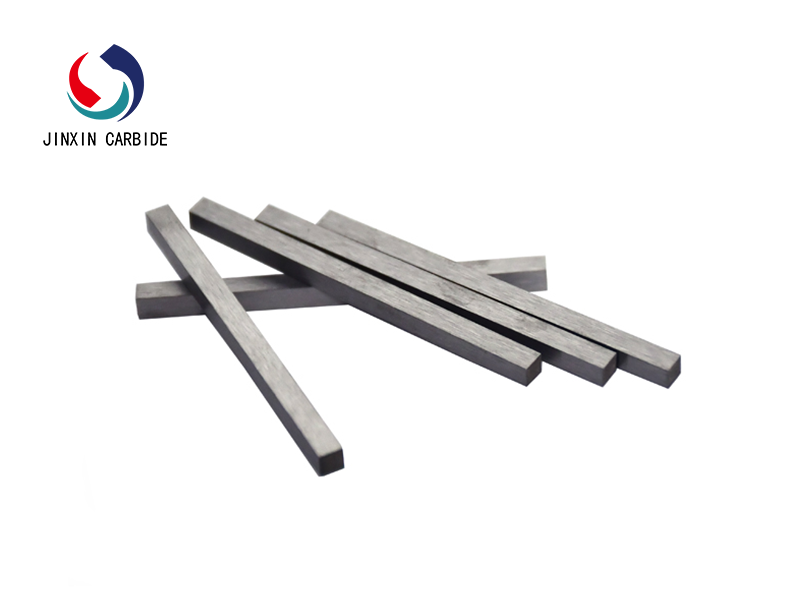

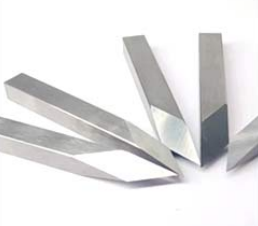

Long strip of cemented carbide

Share with

Product Description

Product introduction

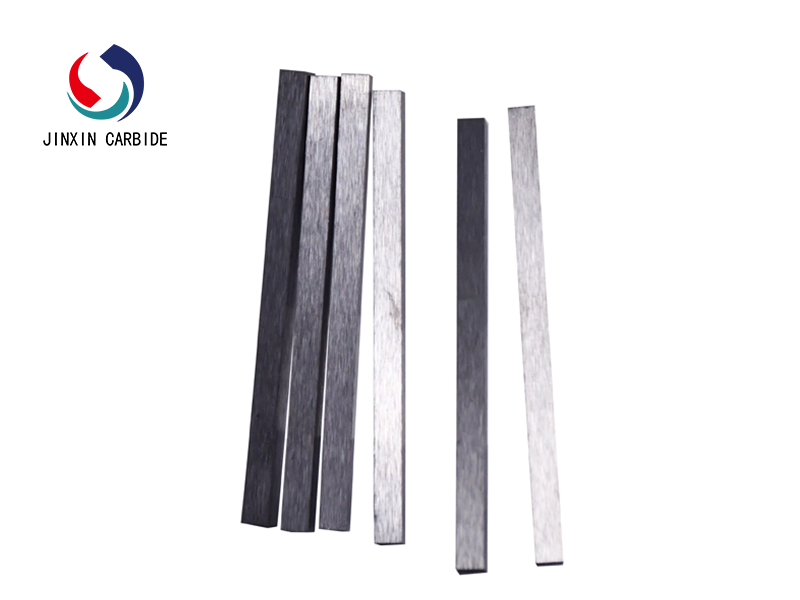

Long bars of cemented carbide are made from high-quality tungsten carbide and binding metals such as cobalt and nickel, manufactured through a precision powder metallurgy process that combines exceptional hardness and toughness, making them suitable for a wide range of industrial applications.

The product uses tungsten carbide as its main structure, combined with bonding metals in precise proportions, then pressed under high pressure and sintered at an elevated temperature—resulting in a dense, stable microstructure. Its hardness exceeds HRA85, enabling it to withstand high friction and impact forces, while maintaining exceptional performance across environments ranging from -40°C to 600°C. Moreover, its service life significantly outperforms that of conventional metallic materials.

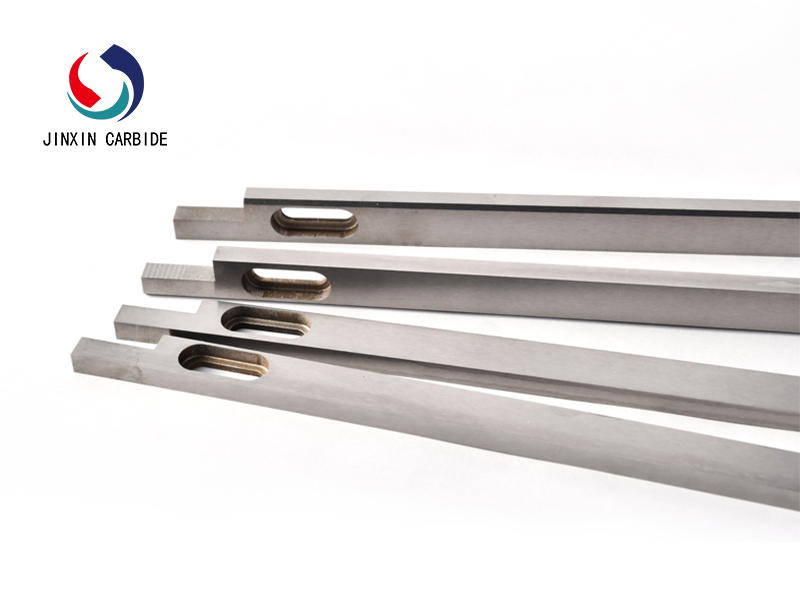

The long-bar design caters to linear processing needs, offering common lengths ranging from tens of millimeters to several meters, along with a variety of width and thickness specifications—and supports customization. It is ideal for manufacturing mechanical tools, stamping dies, mineral-crushing components, and more, enhancing equipment efficiency while reducing maintenance costs, making it a reliable choice for industrial production.

Product parameters

Name: Long carbide cemented bar

Features: High hardness, high wear resistance, high strength, high toughness

Specifications: Complete specifications, customization on demand

Applications: For manufacturing wear-resistant tools such as tools for the wood industry, plastic shredding equipment, etc.; and for producing high-temperature resistant parts, wear-resistant components, shielding-resistant parts, and corrosion-resistant components for the chemical industry.

| Jin Xin Brand | Physical and mechanical properties | Recommended uses | ||

Density g/cm³ | Hardness HRA | Flexural resistance N/mm² | ||

| YG6A | 14.85 | 92.5 | ≥2000 | Fine-grain alloy, offering superior wear resistance compared to JX06, suitable for processing hardwood, raw timber, aluminum profiles, copper bars, and cast iron. Used to manufacture forming blades and wear-resistant components. |

| YG6 | 14.9 | 90.5 | ≥2400 | High wear resistance, suitable for processing hardwood, rough lumber, aluminum profiles, copper bars, and cast iron. Used to manufacture forming blades and wear-resistant components. |

| YG8 | 14.7 | 89.8 | ≥2600 | High hardness and impact resistance, suitable for processing dry wood, softwood, and non-ferrous metal profiles; ideal for manufacturing forming blades and wear-resistant components. |

| YG11 | 14.4 | 88.5 | ≥2800 | High strength, wear resistance lower than JX06A, suitable for manufacturing forming blades and wear-resistant parts. |

| YG13X | 14.2 | 90 | ≥3200 | High strength, suitable for manufacturing progressive dies and other stamping molds. |

| YG15 | 14.0 | 87 | ≥3000 | Suitable for manufacturing stamping dies and wear-resistant parts. Tungsten carbide jaws for crushing hammers. |

| YG12 | 14.2 | 88.5 | ≥3000 | |

| YG20 | 13.5 | 85.5 | ≥3200 | High strength, suitable for manufacturing progressive dies and other stamping molds. |

| YG10.2 | 14.45 | 91.8 | ≥3300 | High wear and corrosion resistance, suitable for processing cast iron, non-ferrous metals, and non-metallic materials. |

| YG2T | 14.25 | 92 | ≥2400 | Fine-grain alloy with high wear resistance, flexural strength, non-stick properties, and thermal resistance. Suitable for processing high-temperature alloys, stainless steel, and high-manganese steel. |

| YG25 | 13.0 | 91 | ≥2200 | Wear resistance and relatively high strength, suitable for processing cast iron, non-ferrous metals, and non-metallic materials. |

| YN11 | 14~14.3 | 88 | ≥2600 | Non-magnetic alloy, commonly used in molds for circular magnetic-field shaping. |

| YN13 | 87 | ≥2700 | ||

| YN15 | 13.8–14.1 | 86 | ≥2900 | |

| YN18 | 13.5–13.8 | 84 | ≥3000 | Non-magnetic alloy, commonly used in magnetic field forming molds for special shapes. |

| YN20 | 13.4–13.7 | 83 | ≥3100 | |

| YN25 | 12.9–13.2 | 81 | ≥3300 | Non-magnetic alloy, commonly used in punches for magnetic field forming dies. |

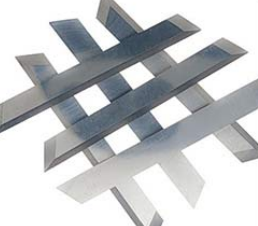

Uses of the long cemented carbide bar

Grooving blade |

Cemented carbide fixed blade |

Microdrills for PCBs |

Cemented carbide blade bars |

Grooving blade |

Blade for cutting lithium batteries |

Cemented carbide blade for chemical fibers |

Tungsten steel bars |

Tungsten steel stamping blade |

Category:

Carbide Strips

Key word:

TC Strips

Carbide Strips

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products