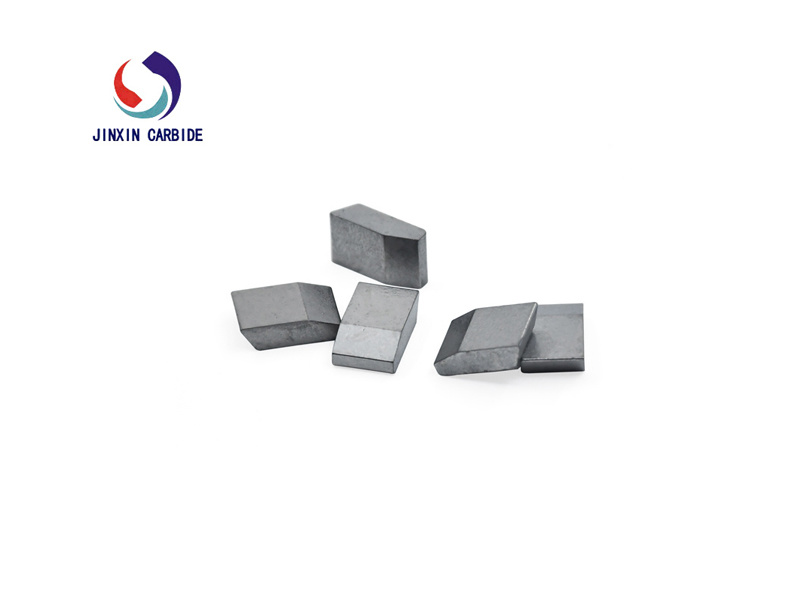

Tungsten Carbide Inserts for Saw Blades

Share with

Product Description

Tungsten carbide saw teeth are a key component of the tungsten carbide saw blade cutting tool, boasting high hardness and excellent wear resistance. Below is a specific introduction:

- Material and manufacturing:

The main component is a tungsten-cobalt alloy, produced using powder metallurgy methods from hard compounds of refractory metals combined with binding metals or alloys. First, the tungsten carbide powder is extruded into shape using a press, and then it undergoes a vacuum sintering process at high temperature and high pressure to fuse the powder particles into a dense, solid mass. Finally, it can be attached to the saw blade and other substrates via an electroplating process and lead-free soldering.

- Common qualities and their uses:

Common grades include YG6, YG8, YG6X, etc. Among these, YG8 is suitable for working conditions with low requirements, such as cutting various types of wood. YG6X, on the other hand, is ideal for cutting very hard woods, like rosewood.

There are also other qualities—let us know your needs, and we’ll recommend the most suitable one for you.

| Grade | Density (g/cm³) | Hardness (HRA) | Flexural strength (N/mm²) | Corresponding ISO standard | Recommended app | Welding suggestion |

| YG6 | 14.6–15.0 | ≥90.0 | ≥1800 | K20 | Suitable for common wood saw blades | Resistance welding can be used, avoiding high temperatures. |

| YG8 | 14.6–14.9 | ≥89.5 | ≥1900 | K30 | Suitable for common wood saw blades, also for common aluminum saw blades | Resistance welding can be used, avoiding high temperatures. |

| JX20 | 14.4–14.7 | ≥90.0 | ≥2000 | K20 | Suitable for common wood saw blades | Resistance welding can be used, avoiding high temperatures. |

| JX25 | 14.3–14.6 | ≥89.5 | ≥2100 | K30 | Suitable for common wood saw blades, also for common aluminum saw blades | Resistance welding can be used, avoiding high temperatures. |

| JX5 | 14.6–15.0 | ≥90.5 | ≥1900 | K10 | Suitable for hardwood materials, recycled wood, and aluminum alloy saw blades | Resistance welding can be used, avoiding high temperatures. |

| JX9 | 14.5–14.9 | ≥90.5 | ≥2000 | K10 | Suitable for the professional cutting of aluminum alloys, copper, and other non-ferrous metals | High-frequency welding is recommended. |

| YG6X | 14.7–15.0 | ≥91.5 | ≥1800 | K10 | For professional wood saw blades | High-frequency welding is recommended. |

| JX10 | 14.8–15.1 | ≥93.3 | ≥2500 | K05 | Suitable for professional saw blades intended for hardwood, also for cutting soft metals. | High-frequency welding is recommended. |

| JX15 | 14.6–15.0 | ≥92.5 | ≥2400 | K05 | Suitable for hardwood saw blades and aluminum alloys | High-frequency welding is recommended. |

| JX35 | 14.9–15.2 | ≥93.5 | ≥2000 | K01 | Suitable for cutting industrial plywood, MDF boards, and laminated panels | High-frequency welding is recommended. |

| JX40 | 12.8–13.2 | ≥90.5 | ≥2000 | P40 | Suitable for professional steel saw blades | High-frequency welding is recommended. |

- Specifications and dimensions:

There are different sizes and shapes available. You can choose based on the wood-working machine model and your specific cutting requirements. We can also manufacture it according to the drawing you provide.

- Performance features:

It has extremely high hardness and wear resistance, can easily cut hardwood and other materials, and boasts a long service life. Additionally, after precise grinding, the edges are smooth, reducing the likelihood of splintering or flying chips during cutting—thus ensuring both enhanced safety and superior cutting accuracy.

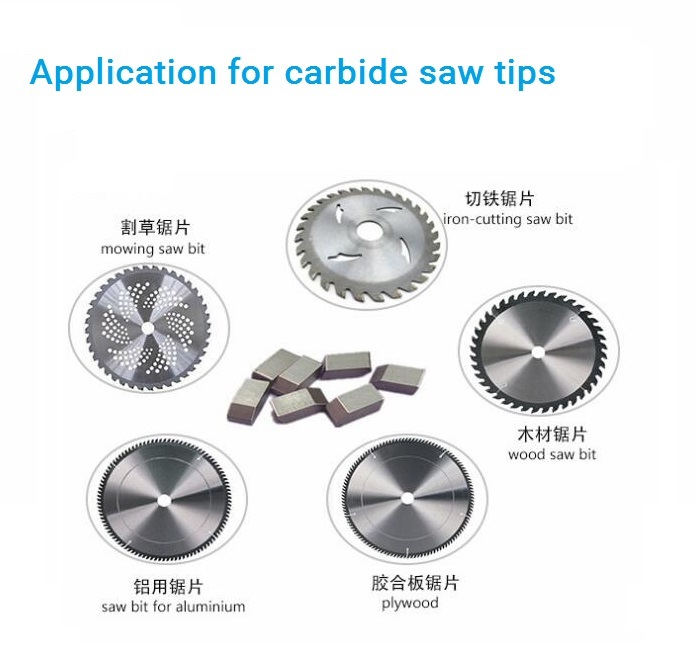

- Scope of application:

Widely used in the cutting and processing of materials such as wood, soft metals, sheets, steel, and plastics—for example, wood cutting, metal tube cutting, and plastic sheet cutting, among others.

Category:

Cemented Carbide Materials

Key word:

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products