COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

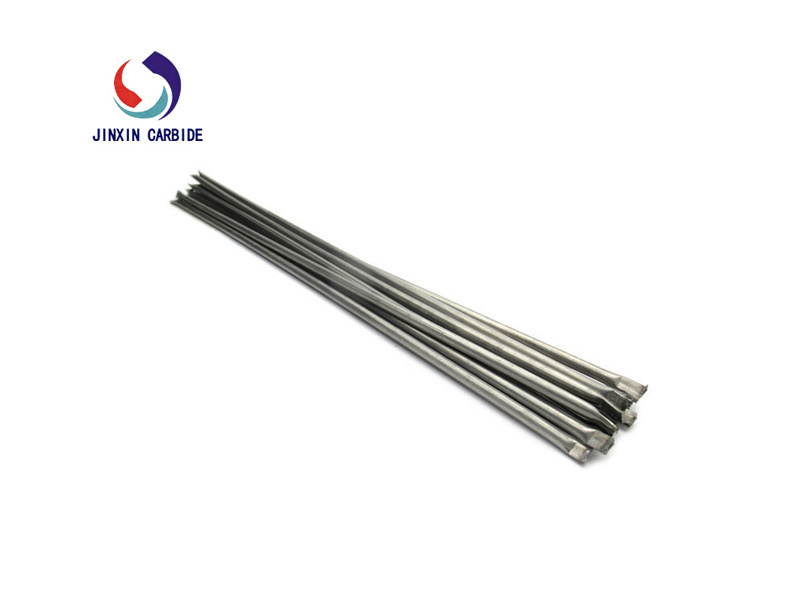

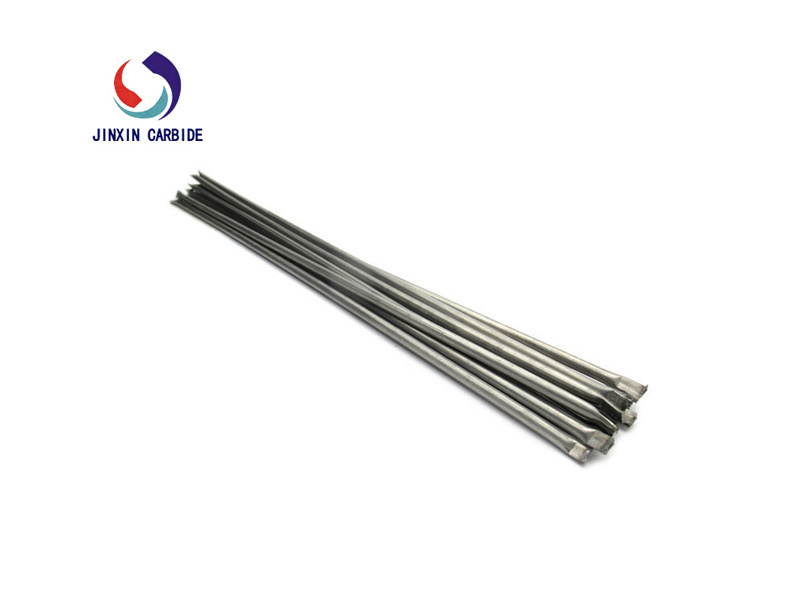

Tungsten Carbide Composite Rod

Share with

Product Description

Product introduction

The cemented carbide overlay welding electrodes are made from granular sintered cemented carbide mixed with an elastic base alloy. They are coated with a special layer of flux and colored to indicate the grain size. The grains of the sintered cemented carbide consist primarily of tungsten carbide with cobalt, achieving a hardness of HRA89-91; the flux metal is either nickel or copper, offering a tensile strength of 690 MPa and a hardness of HB≥160.

Cemented carbide grains utilize sintered tungsten carbide material, with an optimized cobalt content carefully controlled between 5% and 12%, ensuring the wear resistance of the grains as well as their strong bond to the metallic base. In the nickel-copper alloy matrix, copper accounts for between 30% and 35%, resulting in a density of 14.8 g/cm³ and creating a robust supporting structure with a tensile strength of 690 MPa. The special flux coating helps minimize oxidation reactions during the overlay process, ensuring a uniform and orderly distribution of the alloy grains.

Cemented carbide electrodes are primarily used for overlay applications in industries such as oil, mining, coal extraction, geology, and construction—on components that experience severe wear or also require cutting functions. For example: milling shoes, wear shoes, aligners, reamers, drill rod joints, hydraulic cutters, scraper blades, coal mill cutter blades, core drills, pile drills, twist drills, and more.

Main dimensions

| Serial number | Binding agent | Cemented carbide grains (millimeters) | Total length (mm) |

| 1 | Copper/Nickel | 1.6–3.2 | 450/360 |

| 2 | Copper/Nickel | 3.2–4.8 | 450/360 |

| 3 | Copper/Nickel | 4.8–6.4 | 450/360 |

| 4 | Copper/Nickel | 6.4–8.0 | 450/360 |

| 5 | Copper/Nickel | 8.0–9.5 | 450/360 |

| 6 | Copper/Nickel | 9.5–11 | 450/360 |

Method of use

Before overlaying, the oxide layer on the workpiece surface must be removed using an abrasive grinding wheel and degreased with acetone. During the preheating phase, a neutral flame is used to heat the material up to 600–700°C, keeping the flame nozzle 25 mm away from the workpiece surface. In the overlaying process, the base alloy is first melted to create a molten pool, after which cemented carbide grains are evenly spread, ensuring the overlay thickness remains uniform—between 3 and 5 mm in a single layer. Once the overlaying is complete, the area should be covered with insulating material and allowed to cool slowly until it reaches ambient temperature.

Category:

Cemented Carbide Hardfacing

Key word:

Tungsten Carbide Composite Rod

Tungsten Carbide Brazed Rod

Hadfacing Rod

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha