COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

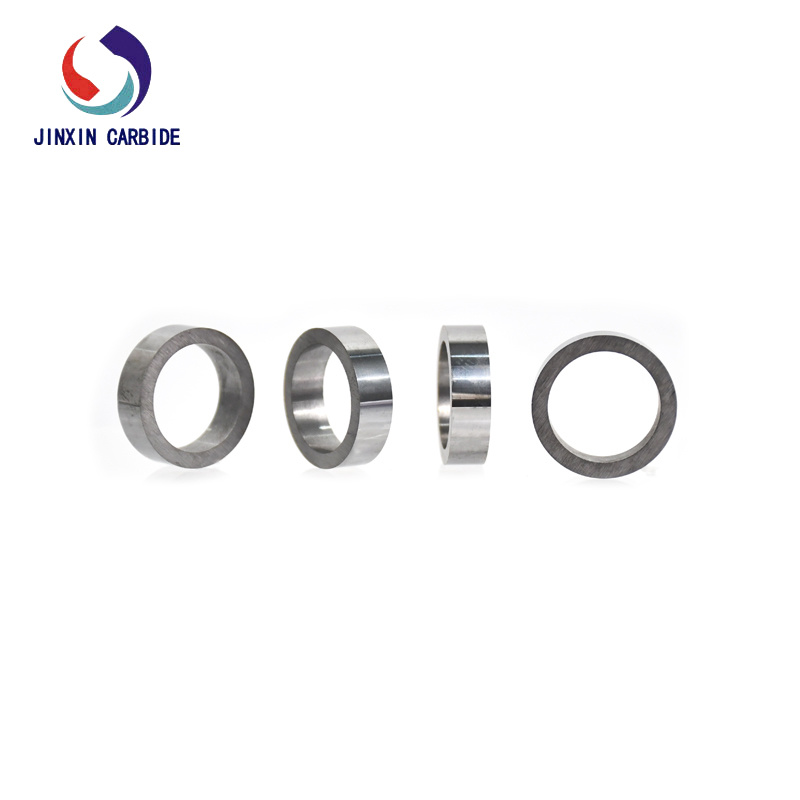

Carbide sealing rings Tungsten is widely used in various industrial pumping equipment due to its high hardness, wear resistance, excellent corrosion resistance, and other exceptional properties—features that are essential for ensuring the efficient and long-term operation of the equipment. Below are some of the key application areas for tungsten carbide sealing rings:

Industrial pumps Tungsten carbide sealing rings are widely used in various types of industrial pumps, such as centrifugal pumps, piston pumps, mixed-flow pumps, and more. These pumps typically operate at high pressures and speeds, handling corrosive media as well. Tungsten carbide sealing rings provide reliable sealing and long-lasting wear resistance, reducing maintenance needs and minimizing pump downtime.

Oil and gas industry In oilfield mining, pipeline and gas pipeline transportation, refining, and chemical processes, tungsten carbide seal rings are commonly used in pumps and equipment—capable of withstanding high temperatures, high pressures, and corrosive media—to ensure the efficient and reliable operation of the machinery.

Chemical processing In the chemical production process, it is often necessary to handle corrosive chemicals, acidic and alkaline liquids, and more. Thanks to their outstanding corrosion resistance, tungsten carbide seal rings are widely used in a variety of pumps and equipment to ensure long-term sealing performance and operational stability.

Mining and Construction Engineering In the field of mine drainage, sludge treatment, sludge transportation, and more, tungsten carbide seal rings can withstand high abrasion and corrosion, ensuring the reliable long-term operation of pumps and equipment in harsh environments.

Water treatment In urban water supply systems, wastewater treatment, industrial water treatment, and more, tungsten carbide seal rings can maintain excellent sealing performance across various water quality environments, ensuring stable operation and the long-term durability of equipment.

On the previous page:

Next page:

Latest information

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha