COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

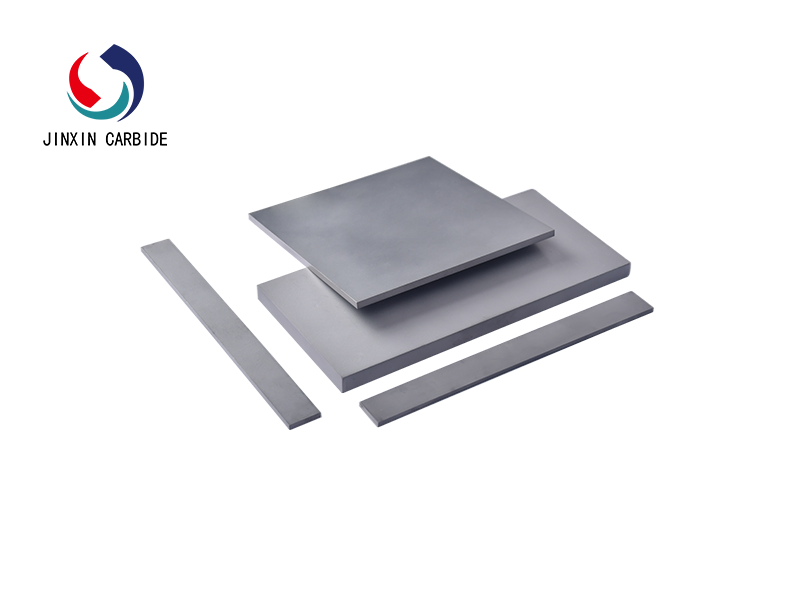

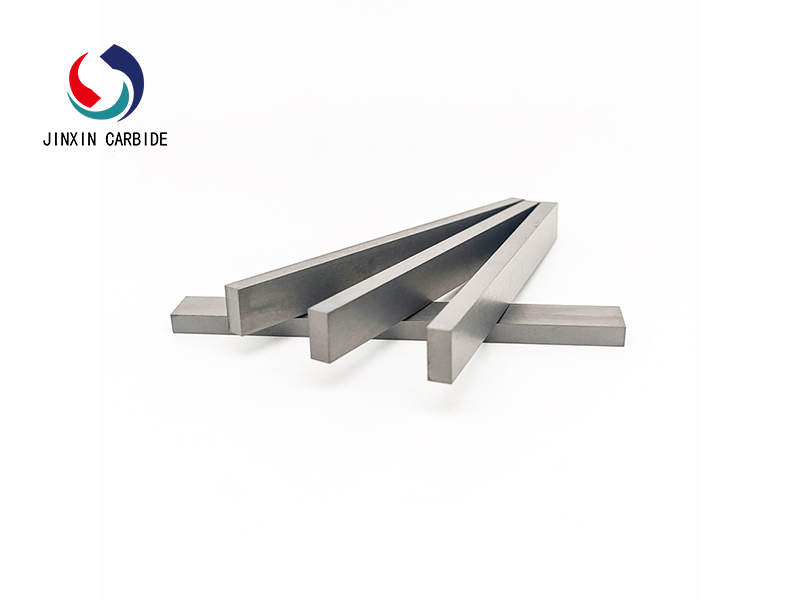

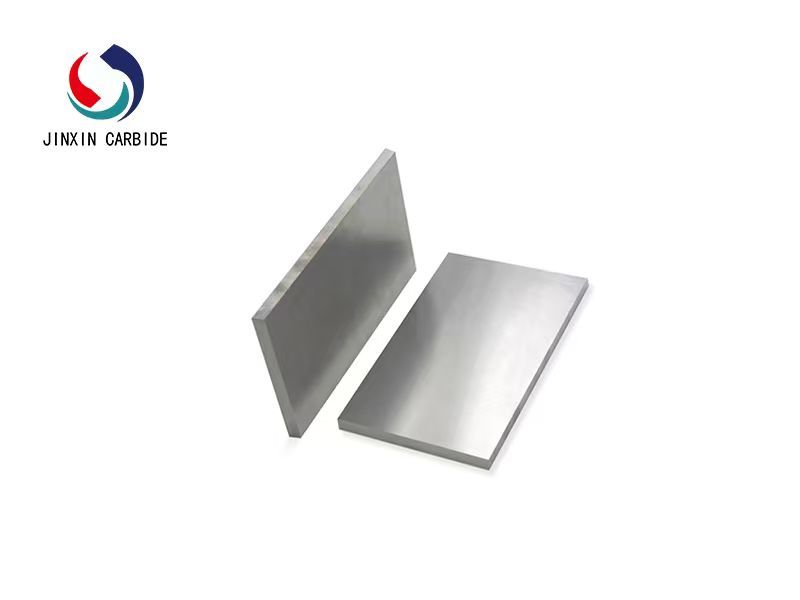

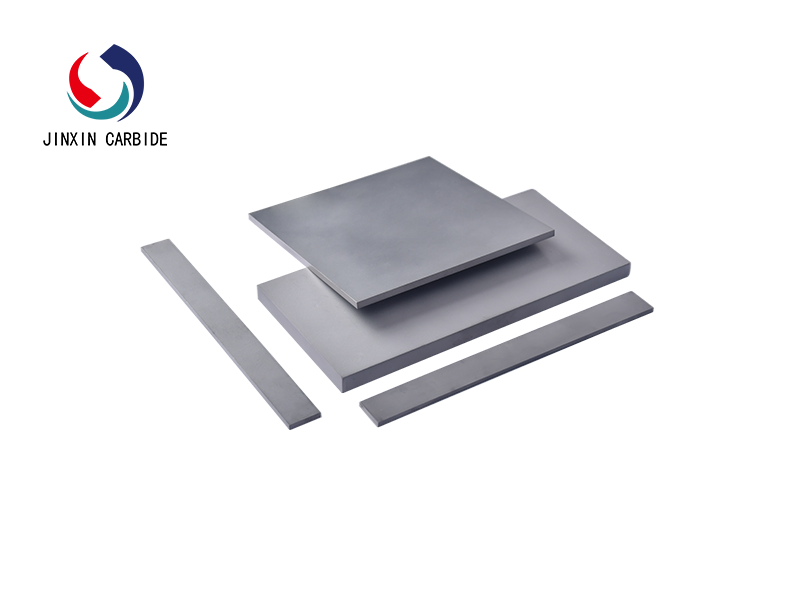

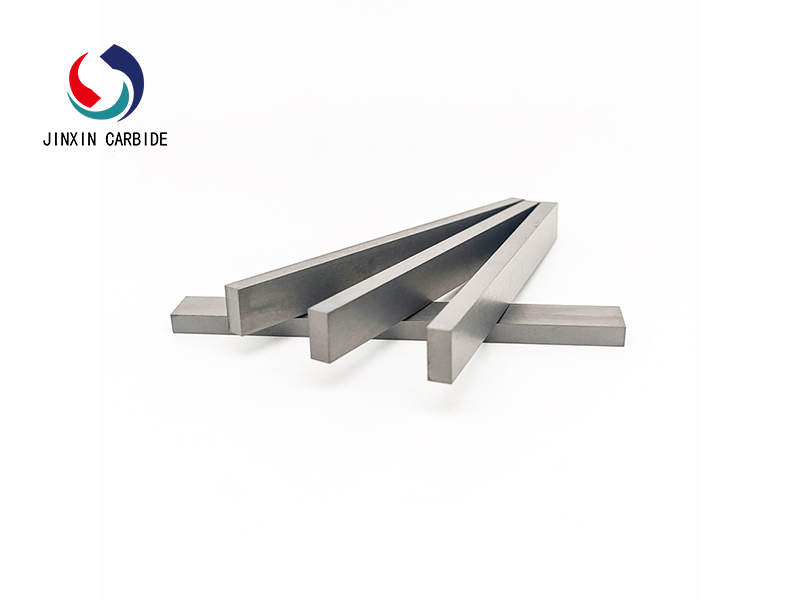

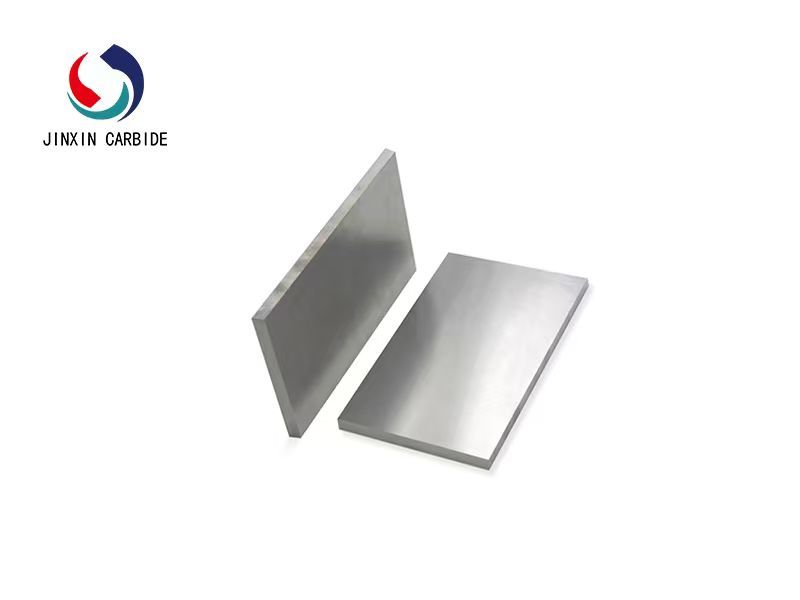

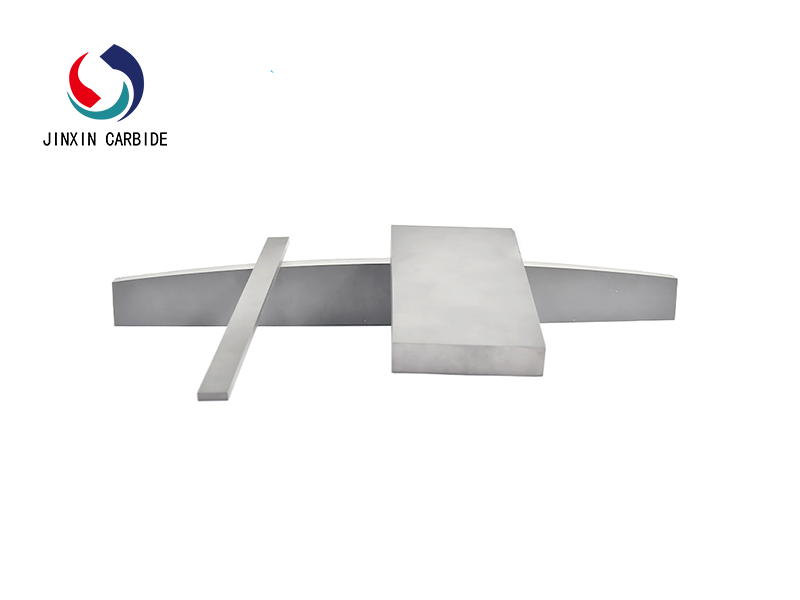

Tungsten carbide plate

Share with

Product Description

Product introduction

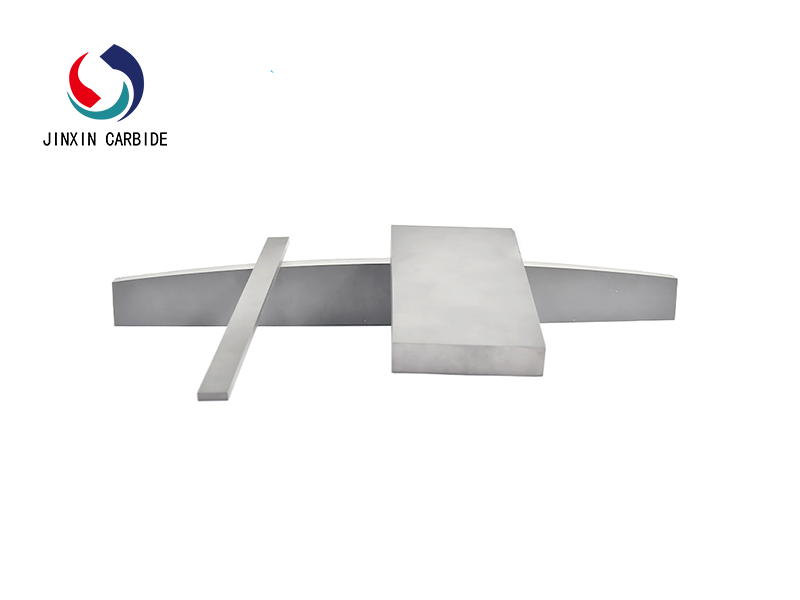

Cemented carbide plates (also known as tungsten steel plates), sometimes referred to as cemented carbide blocks, are high-strength industrial materials manufactured from tungsten carbide powder and cobalt powder using metallurgical processes such as atomization, wet grinding, mixing, pressing, and sintering [2-3]. The product forms include rectangular plates, round bars, long strips, and other profiles, and they are primarily used in the manufacturing of molds, medical devices, automotive components, mining tools, woodworking tools, and chemical equipment.

Cemented carbide plates have a hardness of 86–93 HRA, maintain stable hardness up to 500°C, and retain their thermal hardness between 900–1000°C. They exhibit excellent wear resistance, high compressive strength, and resistance to both acidic and alkaline corrosion, while also boasting a low coefficient of thermal expansion and thermal and electrical conductivity comparable to iron-based alloys. The production process includes spray drying, sintering under nitrogen protection, and defect-detection testing—during manufacturing, impacts are carefully avoided to mitigate the material’s inherent brittleness. By adjusting the ratio of tungsten carbide to cobalt, the material properties can be optimized, making it widely used in applications such as mold core manufacturing, inserts, wear-resistant parts, and sealing components.

Areas of application

1. Suitable for the manufacturing of iron casting rollers and forming blades for high-nickel-chromium rollers;

2. Suitable for the manufacturing of discharge plates, stamping dies, punches, progressive molds for electronic-grade applications, and other stamping dies.

3. Non-standard and special customizations are accepted. The images and online quotes are for reference only; prices vary depending on specifications, raw materials, costs, and order quantity.

Product parameters

| Brand | YG6A | YG8 | YG15 | YG20 | YS2T | |

| International ranking number | K10 | K20 | K30-K40 | K05 | K10-K20 | |

| Cobalt content | % | 6 | 8 | 15 | 20 | 15 |

| Tungsten carbide content | % | 94 | 92 | 85 | 80 | 85 |

| Density | g/cm³ | 14.9 | 14.7 | 14.5 | 13.5 | 14.5 |

| Flexural resistance | MPa | 1850 | 2400 | 2500 | 2800 | 2350 |

| Hardness | HRA | 92 | 89.5 | 87.5 | 85.5 | 92 |

Introduction to performance and usage

| Brand | Introduction to performance and usage |

| YG6A | It is a fine-grained alloy with excellent wear resistance, suitable for manufacturing forming blades and wear-resistant components. |

| YG8 | It possesses high strength, with wear resistance lower than YG6A, making it suitable for manufacturing forming blades and wear-resistant components. |

| YG15 | Suitable for manufacturing stamping dies and wear-resistant parts. |

| YG20 | It possesses high strength, making it suitable for manufacturing progressive dies and other stamping molds. |

| Ys2T | It is a fine-grained alloy with high wear resistance, flexural strength, non-stick properties, and impact resistance, making it suitable for processing high-temperature alloys, stainless steel, and high-speed steel. |

Other brands of cemented carbide plates can be provided according to the user's needs.

Customization of cemented carbide plates

Zhuzhou Jinxin cemented carbide plates can offer non-standard OEM customization, with a maximum length of 2.6 meters, a minimum thickness of 0.2 mm, efficient delivery, and shipping in as little as 8 days.

Category:

Cemented Carbide Plate

Key word:

Product consultation

Attention: Please leave your contact information, and our professionals will reach out to you as soon as possible!

Recommended products

Contact us

Phone:+86 133-9733-9096

Mailbox:13397339096@ojinxin.com

WhatsApp:+86 133-9733-9096

Address: Jiade Industrial Park, Zhuzhou City, Hunan Province, China

The inventory of anti-slip nails is in stock, along with the efficient development of diverse products and superior quality.

Navigation

Request a quote

Copyright © Zhuzhou Jinxin Cemented Carbide Group Co., Ltd

This site supports IPv4 and IPv6.

Powered bywww.300.cn Changsha